Amit Goswami

Current PhD Student

Use of surface coatings in phase-change enhancement

Phase-change heat transfer is common in day-to-day applications, like in cooling of many electronic circuits. The general idea of using a phase change is to exploit the large energy associated in a phase transformation process. For example, condensers are critical units in many power plants. It is observed that the condensation can take place on a surface in two manners: film-wise condensation and drop-wise condensation. Where film-wise condensation refers to the formation of the condensate on a surface in form of a film, drop-wise condensation occurs in form of tiny droplets which when grow bigger with condensation, are removed from the surface. Thus, film-wise condensation limits the direct contact of the condensing vapor with the heat transfer surface due to the presence of the condensate film over the surface. Drop-wise condensation can efficiently drain the condensate in form of droplets, hence continuously has exposed heat transfer surface for maintained and enhanced condensation. Many studies have reported the heat transfer coefficients in drop-wise condensation to be an order of magnitude higher than film-wise condensation owing to this property.

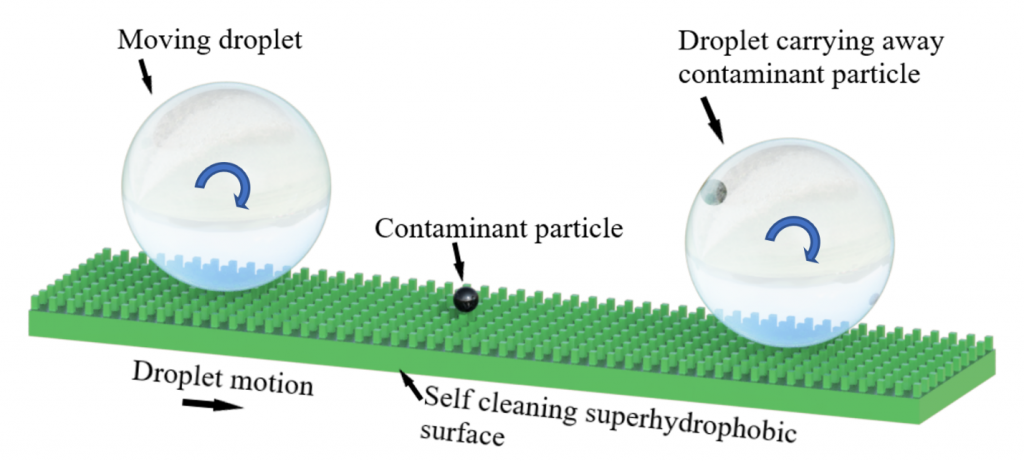

The most commonly adopted technique to achieve drop-wise condensation relies on creating a low surface energy surface which can efficiently remove the condensate droplets. These surfaces show extremely high mobility of condensate droplets, also resulting in a cleaning effect on the surface by the moving droplets. Therefore, low energy surfaces not only provide a high efficiency condensation, but also reduced surface contamination arising from various practical conditions (Figure 1). However, the practical realization of dropwise condensation in industrial conditions still is a challenge. Due to the high temperatures and pressures encountered in most industrial scale heat exchangers (eg. Power plants), even the drop-wise condensation transforms to film-wise mode in short period of time therefore degrading process efficiency. Therefore, the primary objectives of my research work are-

- Identification and development of surface coatings with low surface energy and high antifouling and self-cleaning properties.

- Developing micro/nano surface features to promote condensate removal in severe industrial process conditions.

Profile:

Before joining IT Sligo, I completed my bachelor’s and master’s degree in ‘Mechanical Engineering’ from Indian Institute of Information Technology, Design and Manufacturing, Kancheepuram India in May 2019. In my bachelor’s degree, I specialized in ‘Design and manufacturing’. My master’s specialization is in Advanced manufacturing.

Papers

Submitted manuscripts-

- ‘Surface Modifications to Enhance Dropwise Condensation’, Amit Goswami, Suresh C. Pillai, Gerard McGranaghan*, (Under revision)

- ‘2D Materials for Wastewater Treatments’, Nishanth Thomas, Amit Goswami, Kris O’Dowd, Gerard McGranaghan, Suresh C. Pillai*, (Under revision)

- ‘2D MoS2-based photocatalysts: Structure, mechanisms and environmental applications’, Nishanth Thomas, Snehamol Mathew, Keerthi M Nair, Kris O’Dowd, Parnia Forouzandeh, Amit Goswami, Gerard McGranaghan, Suresh C. Pillai*(Under review)

Under preparation-

- ‘Antifouling surface coatings for heat exchangers’, Amit Goswami, Suresh C. Pillai, Gerard McGranaghan*.

- ‘Advances in marine antifouling nanoscale polymer based coatings’, Amit Goswami, Gerard McGranaghan, Suresh C. Pillai*.